Vinyl chloride was first produced in 1835 but did not go into regular production until the early twentieth century.

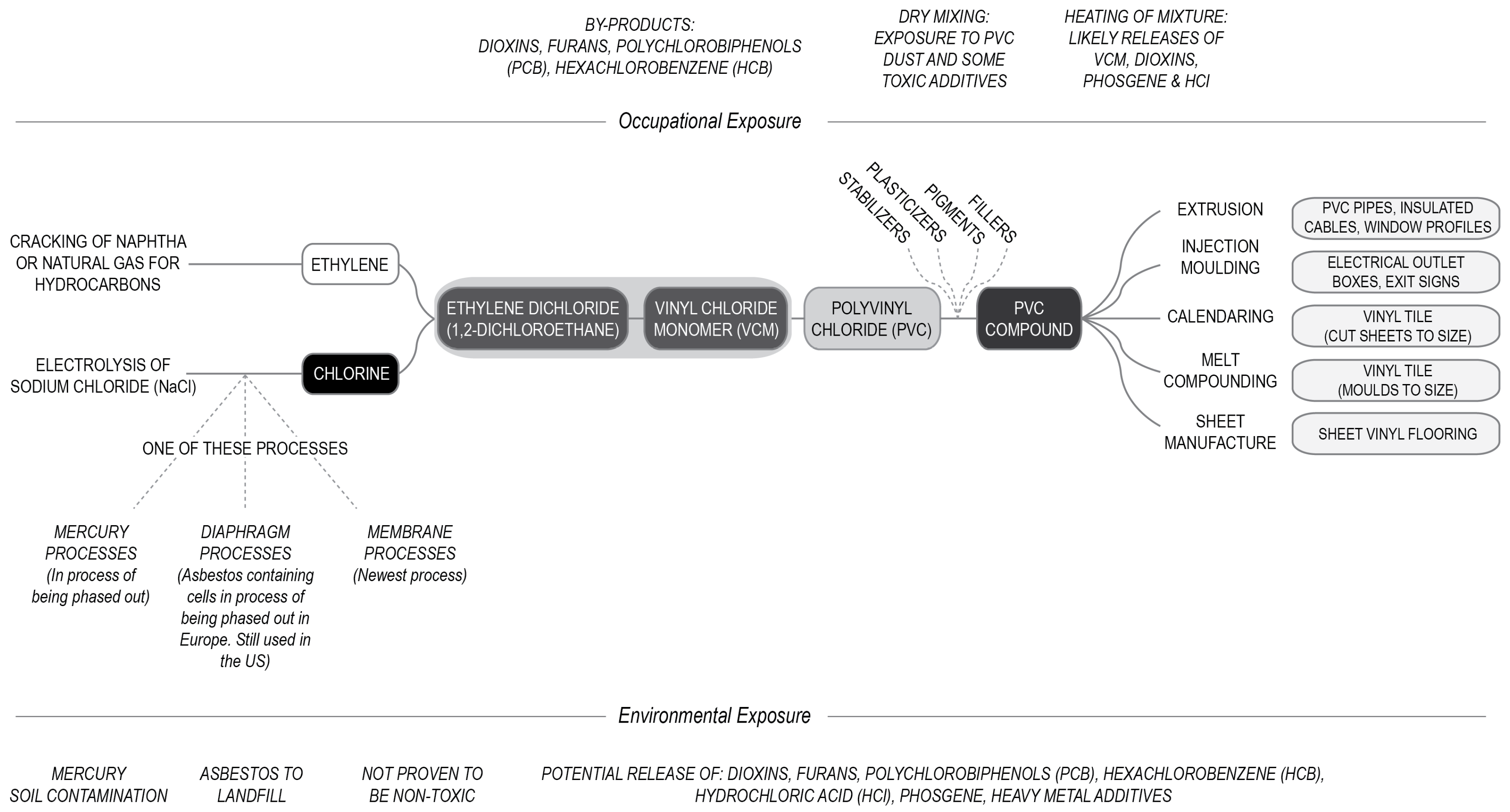

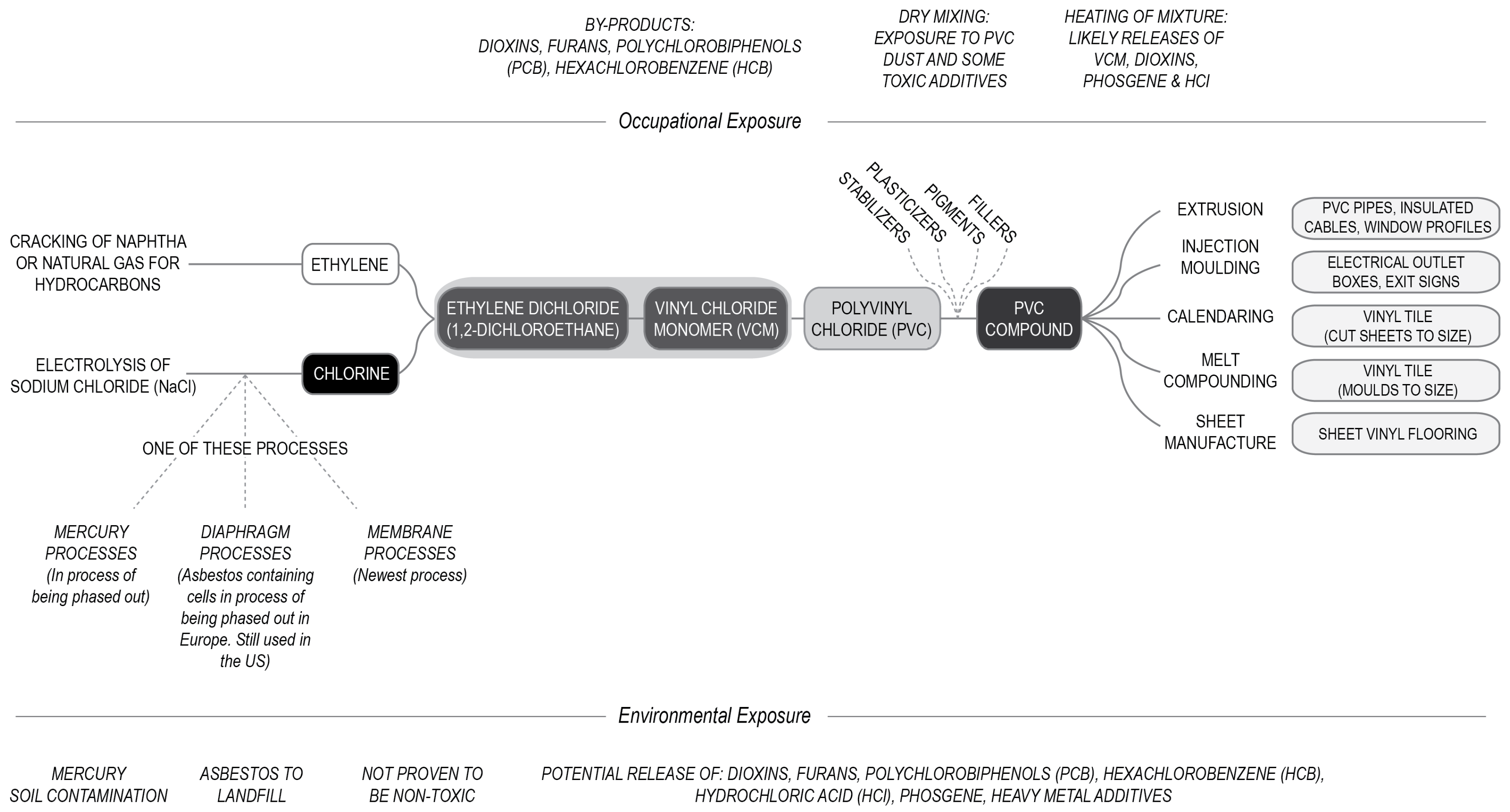

Vinyl chloride manufacturing process.

The process chosen for vinyl chloride production is a combination of two processes direct chlorination and oxychlorination.

The salt is used to obtain chlorine through a process called electrolytic disassociation of salt.

Alternatively watch our short video for an overview of the process and the manufacturing supply chain.

Heavy ends oxy chlorination direct chlorination edc purification edc pyrolysis vcm purification hcl recycle air or o 2 ethylene cl 2 light ends.

Vinyl chloride has been used in the past as an anaesthetic and as an aerosol spray propellant but its principle use has been to produce the polymer polyvinyl chloride pvc or vinyl.

Polyvinyl chloride or vinyl compound is chiefly made from two basic substances salt and crude oil.

Vinyl chloride is produced from ethylene in two step process.

Vinyl chloride is an organochloride with the formula h 2 c chcl that is also called vinyl chloride monomer vcm or chloroethene this colorless compound is an important industrial chemical chiefly used to produce the polymer polyvinyl chloride pvc.

Step 1 producing ethylene dichloride c2h4cl2.

About 13 billion kilograms are produced annually.

Vinyl siding is plastic exterior siding for houses and small apartment buildings used for decoration and weatherproofing imitating wood clapboard board and batten or shakes and used instead of other materials such as aluminum or fiber cement siding it is an engineered product manufactured primarily from polyvinyl chloride pvc resin.

This process is referred to as the balanced process.

Direct chlorination by itself is a process that operates at lower temperatures and produces fewer by products when compared to oxychlorination.

The main polymerization methods include suspension emulsion and bulk mass methods.

Balanced process for vinyl chloride production no generation of hcl 95 of the world s vcm is produced utilizing the balanced process.

The crude oil petroleum or natural gas is used to obtain ethylene.

Vinyl chloride monomer vcm production and manufacturing process 2010 04 28 commercial production of vcm started in the 1920s based on the catalytic hydrochlorination of acetylene but this route suffered from high energy costs and has become obsolete except for china.

Manufacturing polyvinyl chloride pvc is a three step process described below.

Flow sheet of production of ethylene dichloride.