At what point do tyres melt.

Vulcanized rubber melting point.

Trade names include perbunan nipol krynac and europrene this rubber is unusual in being resistant to oil fuel and other chemicals.

Think of melting tyres as trying to unbake a loaf of bread it just can t be done because.

The casting material usually molten metal or liquid thermoset plastic is then poured in through an opening at the top center of the mold.

By staff writer last updated mar 31 2020 8 30 42 am et.

Silicone rubber is an elastomer rubber like material composed of silicone itself a polymer containing silicon together with carbon hydrogen and oxygen silicone rubbers are widely used in industry and there are multiple formulations.

The rubber has been processed with other materials such as carbon to ensure that it doesn t oxidise and therefore burn or melt.

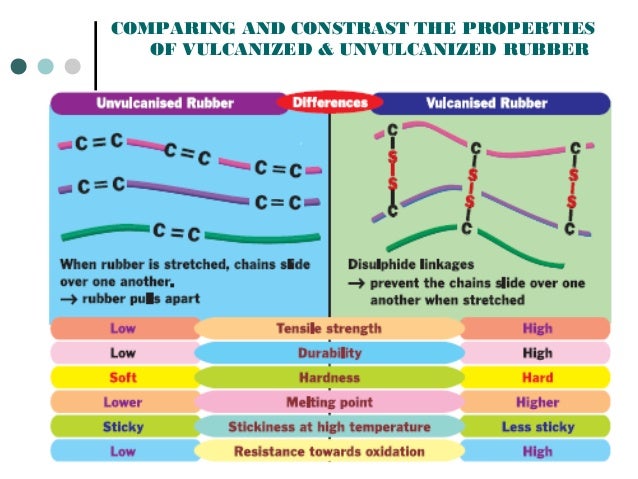

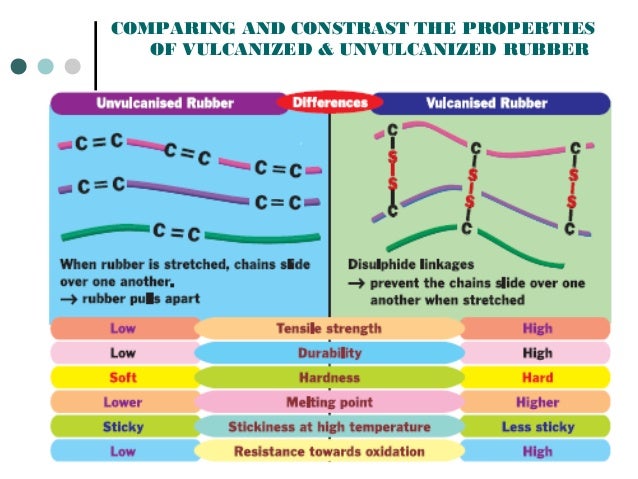

Vulcanised rubber is rubber that has been heated with sulphur.

Silicone rubbers are often one or two part polymers and may contain fillers to improve properties or reduce cost.

The tires are vulcanized which means they ve been through a process that combines the rubber molecules with carbon and other elements to prevent them from oxidizing or burning.

Typically a disc shaped mold is spun along its central axis at a set speed.

However it has also grown to include the hardening of other synthetic rubbers via various means examples include silicone rubber via room temperature vulcanizing and.

Nbr is used in the automotive and aeronautical industry to make fuel and oil handling hoses seals grommets.

A modern vulcanized rubber compound tyre can be thrown into a hot furnace and not melt.

Vulcanized rubber physical properties suppliers cas msds structure molecular formula molecular weight solubility boiling point melting point.

Most modern shoe soles are not rubber as in natural latex based but are some form of plastic heat will melt most thermoform plastic but the problem will be making a suitable mould for the sole.

What is the melting point of rubber.

Spin casting also known as centrifugal rubber mold casting crmc is a method of utilizing centrifugal force to produce castings from a rubber mold.

Vulcanised rubber is prepared in the laboratory by soaking the rubber in a solution of disulphur dichloride or sulphur monochloride in methylbenzene.

Nitrile rubber also known as nbr buna n and acrylonitrile butadiene rubber is a synthetic rubber derived from acrylonitrile acn and butadiene.

The optimum temperature for rubber is 20 c.

Vulcanisation refers to a range of processes for hardening rubbers.

Pure rubber once vulcanised can not be melted or the tires on your car would melt under heavy braking.

At low temperatures around 5 c to 6 c there is a risk that rubber hardens because of crystallization.

Natural rubber is vulcanized to improve its characteristics so that its usage could be wider.

It s why hot rodders can burn rubber without setting anything on fire.